Recently, we welcomed the Wave 1 for 2021 of Business Central (version 18). In it, I spotted some interesting improvements in the manufacturing area, a module that doesn’t often enjoy new features with version updates.

So I’d like to focus in on what I think are some exciting areas for users in this sector.

Variants in Manufacturing

In version 18, two new functions are now available.

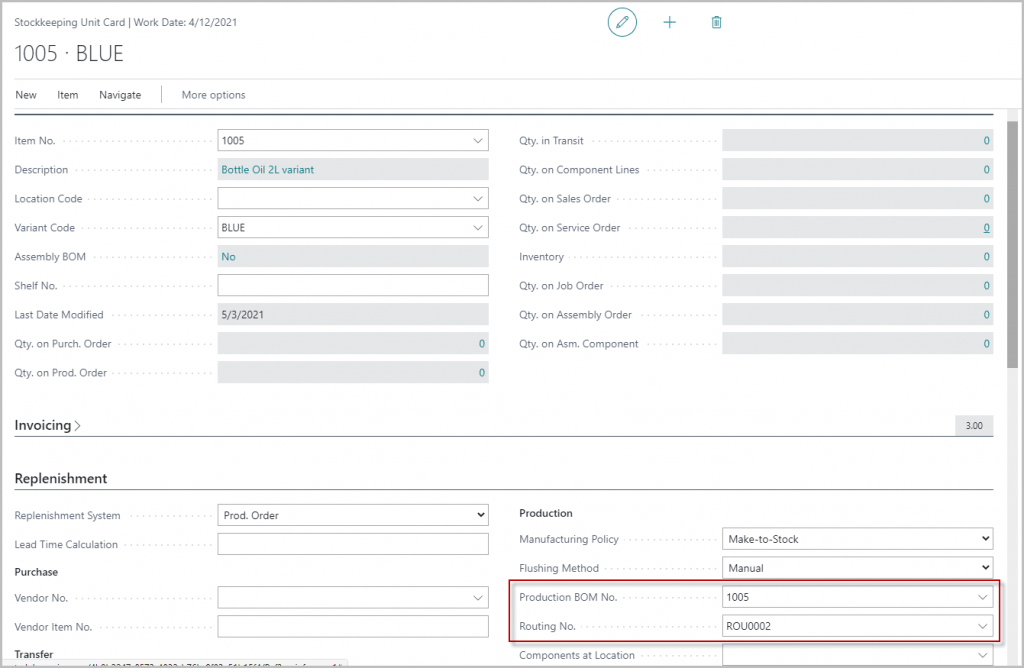

The first one is related to variants. As you may know, the variant code is usually used in Microsoft Dynamics 365 Business Central if you want to manage several items that are almost identical and differ slightly, only in color for example. Previously, if you wanted to manage the production of this item, there was no way to manage BOM and routings depending on the colors. And there was no other choice than to create as many item cards as there are different colors. Unproductive to say the least.

In this new version, Microsoft introduces a BOM and a routing at the stockkeeping Unit level. Thanks to that, the user can have a different BOM and routing for each variant code of an item.

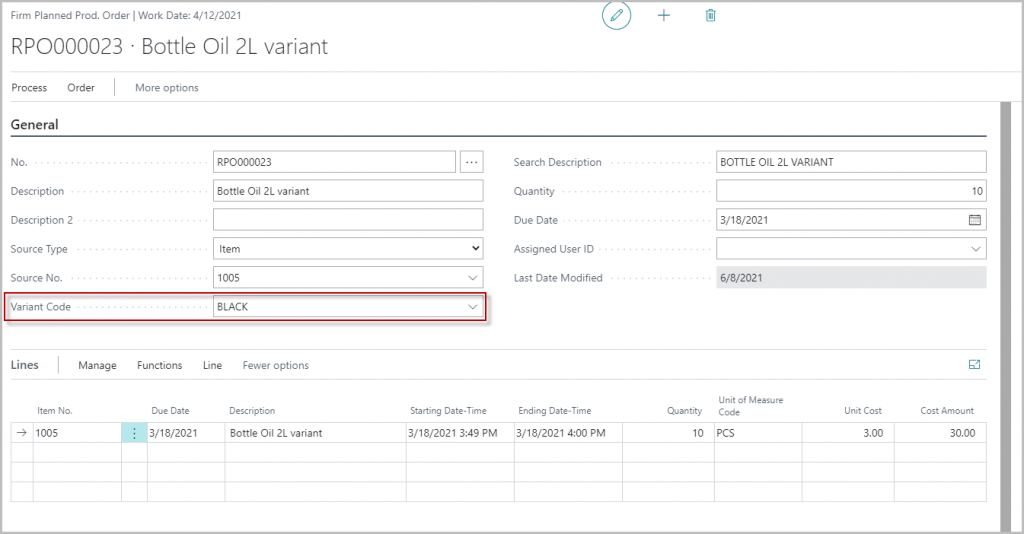

The variant code was also added at the header of a production order in order to take into account this functionality, when a production order is created manually or by using the sales order planning feature.

But the integration is not totally complete. Indeed, the planning worksheet (MPS and MRP engine) doesn’t take into consideration BOM and routing from the stockkeeping Unit. Too bad! I hope this is only a delay and this will be addressed in the next version…

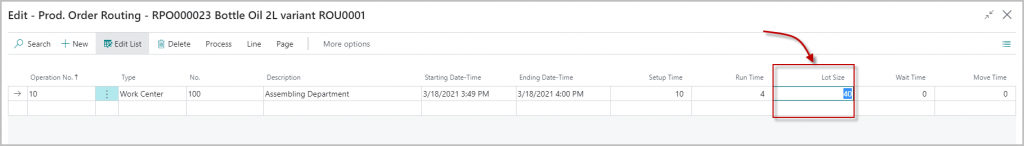

Lot sizes in the production process

The second improvement in manufacturing is the possibility to define a lot size at various stages of the production process. In previous versions of Business Central, the lot size can be set only in the routing card. But in this current version, this lot size can be managed from the routing version card, planning worksheet and production order routing card. As a result, the user gains more flexibility on the definition and the management of production processes.

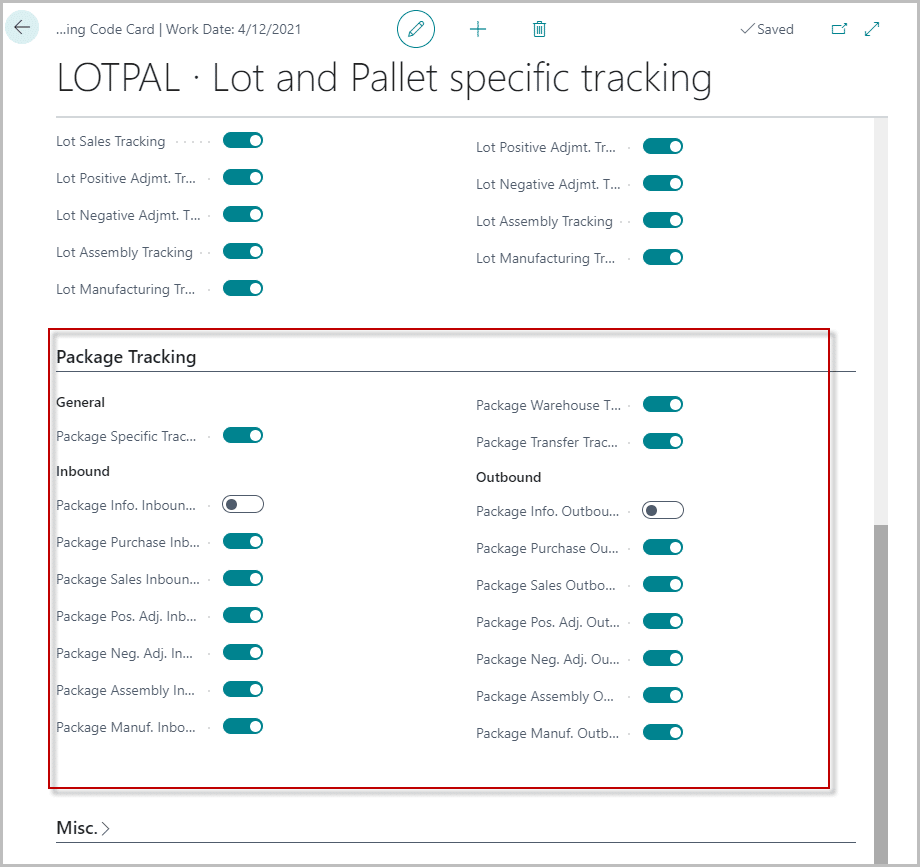

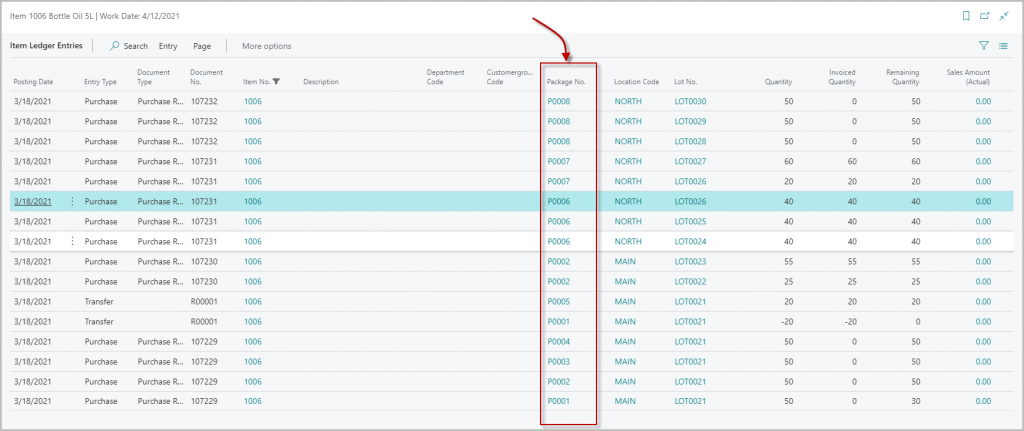

Additional dimensions on Item tracking

This is THE feature I was waiting for!

Microsoft introduces a new dimension in the item tracking management.

It works as a third dimension completing existing Serial No. and Lot No. item tracking.

This dimension can be used to track package or pallets with the same processes as lot tracking, for example.

But beware about using this function as it is, without having in mind the limitations behind it. For example, if you want to manage pallet tracking in your inventory, you may need to add developments in order to link the Pallet No. to the Series No., so you would have to make sure that this pallet cannot be stored in two bin codes at the same time.

What about you?

What do you think of the latest release of Business Central, have you seen some of the improvements you have been waiting for, covered off? Please share your thoughts.

Originally published on LinkedIn.